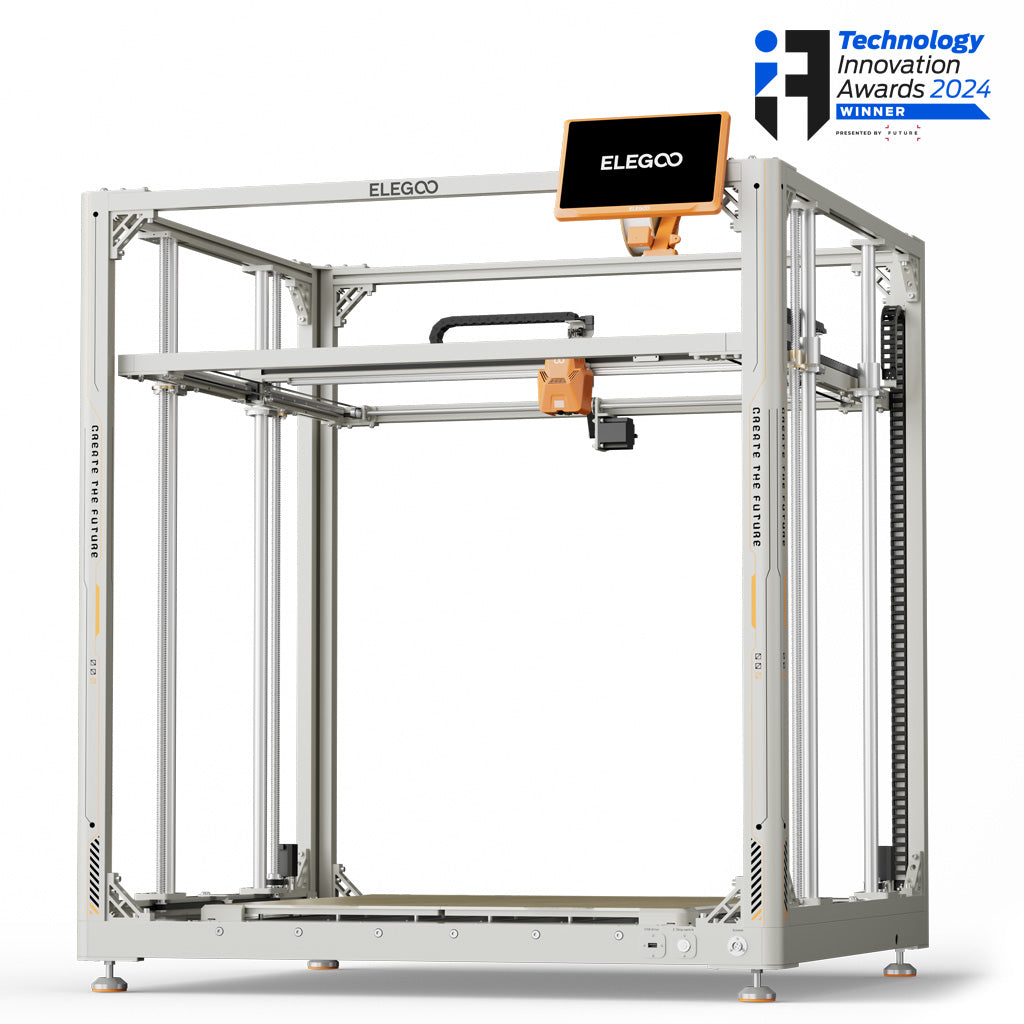

Elegoo Orange Storm Giga Filament Printer TL4982

Key Features

Gigantic in Size

With a colossal build volume of 800 × 800 × 1000 mm, this industrial-grade FDM printer handles oversized models without splitting—reducing prep time and increasing throughput.

Idea: include a short video or 3D mockup to show scale.

Efficient Heated Bed

Four independent 410 × 410 mm PEI magnetic high-temperature plates (max 100 °C) heat simultaneously to 100 °C across the full 820 × 820 mm area in ~17 minutes (ambient 25 °C). Heat only the needed zone automatically or control each plate manually for energy savings.

Fast Printing

Powered by a 64-bit 1.5 GHz quad-core SOC (RK3328) for strong compute and up to 6× speed gains—maximum 300 mm/s (150 mm/s recommended), outstanding for a printer of this size.

Multi-Nozzle Printing

Add up to three extra printheads on the X-axis for four-nozzle simultaneous printing (four copies at once). Equip each nozzle with the same material in different colours to produce four colour variants in one run. Max power 1,530 W; add ~100 W per additional head—ensure your facility can support the total load.

Powerful Cooling Fans

Dual-sided intelligent cooling for consistent part quality: two 5015 ball blower fans plus one 4010 ball axial fan. Fans auto-stop after prints to save energy, lower noise, and extend lifespan.

High-Quality Craftsmanship

Rigid, integrated frame with linear guides on X and Y for stability and longevity. Upgraded Z-axis rods improve smoothness and levelling precision. Carbon-steel round bases with rubber anti-slip pads keep the machine planted.

Powerful Extrusion System

Brass nozzle up to 300 °C for high-temperature materials. Dual-gear direct extruder and titanium heat break ensure steady flow; 60 W ceramic heater delivers rapid, stable heating. PID auto-calibration and built-in acceleration sensor reduce vibration and keep temperatures precise.

Nozzle: 0.6 mm (included); options: 0.4 / 0.8 / 1.0 mm.

Auto-Leveling

Automated mesh levelling streamlines setup on the ultra-large bed.

Caterpillar Cable Tracks

Durable drag-chains protect and guide cables during long-travel moves.

Filament Detection & Power-Loss Recovery

Resume prints after outages and avoid failed jobs from filament breakage.

Portable 10.1" HD Capacitive Screen

Large, responsive touchscreen makes operation clear and convenient.

User-Friendly Belt Knobs

Quickly fine-tune belt tension for peak print quality.

Large Spool Holder

Supports heavy-duty 5 kg spools for uninterrupted large builds.

What's in the Box

| OrangeStorm Giga 3D Printer | Main unit |

|---|---|

| Printhead | Primary extruder assembly |

| Screen | 10.1" HD capacitive touchscreen |

| Levelling Plates ×2 | Assists with initial setup |

| Spool Holder Arm & Spool Holder | Includes detached 5 kg spool holder assembly |

| Filament Breakage Detectors ×2 | Runout protection |

| Z-axis Cable Track Clips | Caterpillar/drag-chain clips |

| Z-axis End Stops ×2 | Limit switches |

| Filament Guide Assembly | Guides filament path |

| Power Cable | Mains lead |

| Levelling Card | Bed calibration aid |

| Grease | Maintenance |

| Profile Corner Brackets ×8 | Frame accessories |

| Tools & Fasteners | Assembly and service kit |

| User Manual | OrangeStorm Giga documentation |

Specifications

| Product Model | OrangeStorm Giga |

|---|---|

| Printing Technology | FDM (Fused Deposition Modeling) |

| Frame Material | CNC machined aluminium extrusion |

| Voltage / Power | 100–120 VAC / 220–240 VAC, 50/60 Hz; 1530 W (single head; +100 W per additional head) |

| File Transfer | Wi-Fi, USB, LAN |

| File Formats | STL, OBJ |

| UI Languages | English, French, German, Russian, Italian, Spanish, Japanese, Chinese |

| Build Volume | 800 × 800 × 1000 mm |

| Printing Platform (PEI Area) | 820 × 820 mm (four independent 410 × 410 mm plates) |

| Machine Size | 1,224 × 1,164 × 1,425 mm |

| Package Size | Bottom + XY: 1,350 × 1,215 × 420 mm; Z-axis ×2: 1,350 × 1,215 × 350 mm |

| Maximum Machine Activity | 1,224 × 1,520 × 1,570 mm |

| Max Nozzle Temp | 300 °C |

| Max Bed Temp | 100 °C (ambient 25 °C) |

| Filament Compatibility | PLA / PETG / TPU |

| Resume Printing | Yes |

| Filament Detection | Yes |

| Max Tool-Head Speed | 300 mm/s |

| Max Tool-Head Acceleration | 5,000 mm/s² |

| Net / Gross Weight | 104 kg / 145 kg |